ColWear Plates are vacuum powder fused wear plates coated with Colmonoy® NiCrBSi or Wallex® CoCrNiW powder matrix, with or without Tungsten Carbide (WC). ColWear Plates:

ColWear Plates offer a unique combination of properties that suit a wide range of applications due to the inherent properties of the fused Colmonoy® (nickel) or Wallex® (cobalt) coating.

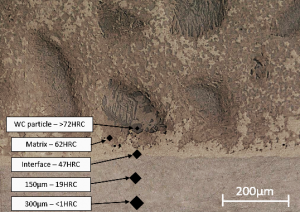

Optical micrograph (original at 500x magnification) and measured hardness values (HRC) of a ColWear Plate at varying positions within the cross section indicating a clean interface, with no dilution of the base plate and regions of ultra-high hardness due to homogeneous dispersion of tungsten carbide.

ColWear Plates are vacuum powder fused wear plates coated with Colmonoy® NiCrBSi or Wallex® CoCrNiW powder matrix, with or without Tungsten Carbide (WC). Typical examples below, however, additional ColWear Plates are available to suit your specific application. We continue to make metals work harder with new and innovative alloys that outperform competition.

Very smooth surface finish (nominal Ra = 3-4μm)

Excellent abrasion and corrosion resistance

Suitable for high impact energy applications

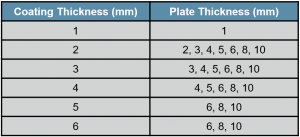

ColWear Plates are available in a variety of standard and customised plate sizes, plate thickness and coating thickness combinations.

Due to the thin, lightweight plate design, ColWear Plates provide resource, costs and usability benefits:

Choose the right wear plate for your specific application.

Standard Plate Sizes*

Plate & Coating Thickness Combinations*

*Non-standard plate sizes & coating thickness available

Need help choosing the right wear plate for your specific application?