Wall Colmonoy’s range of ColWear Plates have outstanding metallurgical and physical properties making them a unique and effective solution to the most aggressive wear problems, including high-temperature corrosion, abrasion, erosion and corrosion.

ColWear Plates effectively combats combinations of wear issues, enhancing performance even in the toughest of applications. They also extend lifetime of single wear environments versus other types of wear plate.

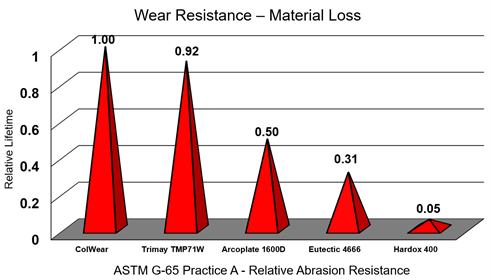

ColWear Plates offer significantly improved abrasion resistance versus common industrial alternatives of wear plate. ColWear Plates exhibit lowest ASTM G-65 Practice A mass loss vs the competition.

ColWear Plates provide excellent corrosion resistance for both aqueous and hot gas corrosion environments due to the chemistry of the Colmonoy® super alloy matrix.

ColWear Plates can also be manufactured using stainless steel and exotic nickel super alloy base plates for further extension of high temperature capability in corrosive environments.

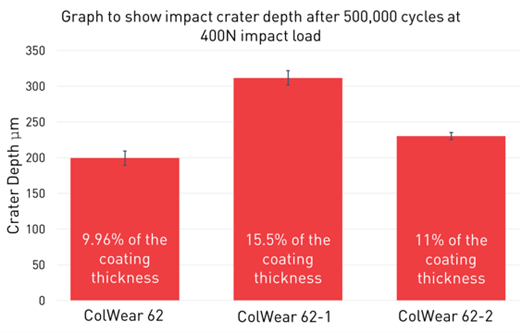

ColWear Plates are an outstanding solution to repeatable high energy impact applications.

Results show measured coating degradation of ColWear Plate after repetitive impact of a 6mm diameter Tungsten Carbide ball on the coating of ColWear Plate.

ColWear 62 exhibits the best repetitive impact performance with less than 10% coating degradation after 500,00 impact cycles:

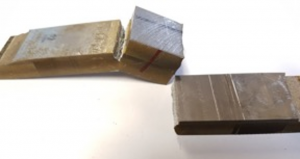

As a powder-fused wear plate, ColWear Plates produce a coating with excellent coating adhesion, ensuring no delamination of the coating in service.

ColWear Plates maintain excellent coating adhesion characteristics, where the coating has outlasted the base plate at high tensile stress.

Bond strength performance on test derived from ISO 4587 (lap shear test).

Typical bond strength:

Standard Spray & Fused coatings are typically produced with adhesive strength of ~500MPa as per Otsubo et al. (2000).

“Interface Reaction between Nickel-Base Self-Fluxing Alloy Coating and Steel Substrate”. Journal of Thermal Spray Technology, 9(2), 259-263

ColWear Plates retain hot hardness of the matrix alloy for extended performance when elevated temperatures are experienced in service.

Ballistics testing conducted against BS EN 1063 & STANAG 4569 with defined ballistic projectile, projectile velocity, and distance.

ColWear Plates are bulletproof with certain combinations of base plate & coating thickness against levels of BS EN 1063 & STANAG 4569 test standards:

BS EN 1063 level 6 impact site where projectile has been absorbed by ColWear Plate.