Wall Colmonoy engineers as cast or fully machined components for the Food and Beverage industries – offering an integrated approach of cast, heat treated, or fully machined components – all from one source.

Seaming Chuck, Homogenizer Valve, Impact Ring, Seaming Roll and Impact Head made from Wallex® for Food Processing, Packaging and Canning Industries

Components for Food Processing, Packaging and Canning are produced using Colmonoy® and Wallex® alloys including:

Components are made from Colmonoy® (nickel), Wallex® (cobalt) or customer-specific alloys using the casting methods of Investment, Centrifugal, Sand or Hot Isostatic Pressing (HIP). Over the last 50 years, our technical team has amassed a wealth of knowledge and know-how turning rigorous requirements into economically viable solutions. Our engineers can advise optimum alloy selection and process to suit specific needs.

Investment – offers design flexibility, close dimensional control, consistency & repeatability, cost savings.

Centrifugal or Spin – is used to produce high integrity densely structured, cylindrical components like bushes and sleeves.

Sand – is typically used to produce larger components in smaller batches. It is capable of making mostly complex shapes using relatively inexpensive wood or resin patterns.

Hot Isostatic Pressing – forms pore free bars or tubes with a fine grain homogeneous structure that enhances the physical properties of the cast alloy.

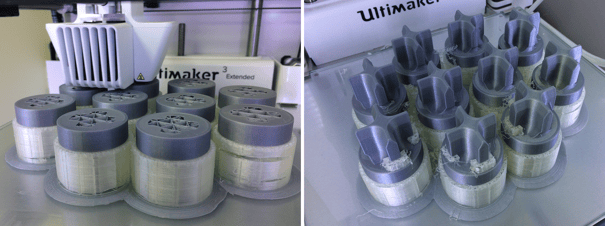

Wall Colmonoy’s castings are processed through applied technologies such as automation, collaborative robots, data analytics – embracing Industry 4.0. With an extensive laboratory and deeply experienced team of Material Scientists and Engineers, Wall Colmonoy can undertake R&D, Rapid Prototyping, and New Product Development. For rapid prototyping, the team implements 3-D printed investment patterns and tooling, reducing the necessity for tooling on small batches and product qualification. Quality castings are assured through advanced laser measurement techniques.

Wall Colmonoy has an ongoing commitment to high quality manufacture and with its on-site laboratory and test facilities offers certification to national and internationally recognised standards. Each engineered component goes through a reassuringly stringent inspection process before final delivery. We maintain the quality assurance of ISO 9001.

A proud member of Cast Metals Federation.

Wallex® Food Contact Material Declaration CMRes2013 GB4806.9-2016

Rapid Prototyping Investment Casting Pattern on Shutter Valves for Food Industry Components by 3-D Printing

Wax moulds of Valve Seats and Seaming Chucks prior to performing Robotic Shelling process

Confirming accuracy and quality of Mushroom Valve using state-of-the-art Optical Measurement Stations to ensure SPC

CONTACT

Wall Colmonoy Limited

Darren House

Alloy Industrial Estate

Pontardawe, Swansea,

Wales (U.K.) SA8 4HL

E: componentsales@wallcolmonoy.co.uk

T: +44 (0) 1792 860647