The latest in news, events, and technical articles

The products and services that Wall Colmonoy provides play an integral role in many industries that are instrumental to our everyday lives.

Our products extend the life of others – making the world a cleaner place: fewer replacements, less downtime, waste, material usage, and energy consumption.

Read about some the ways we do this.

Reducing Emissions & Improving Fuel Economy

EGRs, Catalytic Convertors, Fuel Cells and Heat Exchangers

Exhaust Gas Recirculation units (EGR’s), Catalytic Converters, Fuel Cells and Heat Exchangers for aerospace, automotive and HVAC industries reduce emissions and improve fuel economy. Wall Colmonoy manufactures Nicrobraz® (nickel-based) brazing products, which are used extensively in the manufacture of these products.

To meet the requirements of present and future emission laws, EGRs are commonly deployed in diesel engines to reduce the concentration of NOx. EGRs are usually brazed under high vacuum conditions using nickel-based filler metals to achieve good metallurgical bonding. Read about Nicrobraz® and EGRs in Nicrobraz News Issue.

A catalytic converter is an emissions control device that converts toxic gases and pollutants in exhaust gas to less toxic pollutants by catalyzing a redox reaction (an oxidation and a reduction reaction).2

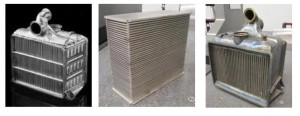

Exhaust Gas Recirculation unit (EGR), Catalyst Unit, Heat Exchanger, Fuel Cell

Read more in Brazing News

Efficient Combustion, Lower Energy Consumption and Longer Lasting Parts

Heat Exchangers for Aerospace, Energy and Defense

Aerobraze Engineered Technologies, a division of Wall Colmonoy, specializes in the manufacture of new design and overhaul of Fin & Plate and Tube & Shell Type Heat Transfer Equipment for aerospace, energy and defense industries.

Wall Colmonoy’s Aerobraze Engineered Technologies, Oklahoma City, recently won a full and open competition conducted by the United States Air Force for a multi-year, multi-million dollar contract for the overhaul of the F-16 Primary and Secondary Heat Exchangers.

In Brian Martin, General Manager for Aerobraze Oklahoma City, stated, “As a major manufacturer and overhauler of heat exchangers for the USAF for over 33 years, it is with great pride that we continue to provide support to the United States Air Force. This new award demonstrates our ongoing commitment to increasing efficiency and cost savings for our customers, through extending the life of critical components for the aerospace industry.”

In 1950, Wall Colmonoy developed high temperature furnace brazing, which is used extensively in the heat exchanger manufacturing process. Having pioneered the very first heat exchanger overhaul procedures, Wall Colmonoy continues to deliver significant cost savings and performance improvements to customers.

Tubular Heat Exchanger, Embraer Heat Exchanger Core, Fin & Plate Heat Exchanger

Read more on Heat Exchangers here

Reducing Greenhouse Gas Emissions and Providing Electricity to Power Homes and Businesses

Waste-to-Energy and Biomass Plants

Waste-to-Energy and Biomass is part of a global clean power generation solution, and it is fast becoming one of the largest energy resources in the world. The rising cost of using landfill has encouraged more recycling of waste and has also led to greater use of incineration processes.

A new generation of Waste-to-Energy (WtE) and Biomass installations are being built to transform waste, such as wood and waste, into usable energy to power homes and businesses – reducing greenhouse gas emissions.

Waste-to-Energy Plants burn municipal solid waste (domestic waste/refuse like food, plastic, paper) etc. to generate energy in the form of electricity and/or heat. The problem is erosion because burning very hard materials like plastic.

Biomass is a sustainable fuel that can deliver a significant reduction in net carbon emissions when compared with fossil fuel. Biomass Plants burn wood chip, chicken litter, straw, timber etc. to produce electricity, methane gas or transportation fuels to generate electricity from the burning waste and biomass products.

Products burnt in both Waste-to-Energy and Biomass Plants have abrasive compounds and produce harsh conditions within the incinerator / boiler which can significantly shorten the lifespan of key components.

The lifespan of boiler walls, super heaters, economisers and other boiler components can be greatly reduced due to this erosive and corrosive environment. Failure of such parts leads to outages and significant loss of revenue to Waste-to-Energy and Biomass companies.

Wall Colmonoy offers a range of alloys and application techniques to suit the specific boiler/incinerator environment and significantly extend the life of components such as super heater tubes, plates, boiler tubes, grate bars and soot blowers.

Read about how Colmonoy® Surfacing Alloys extend the useful life, minimize downtime, and improve efficiency in Waste-to-Energy Plants here

Protecting and Prolonging a 100% Recyclable Product and A Product from Nature

Glass Container

Glass is 100% recyclable material. Glass is a product from nature that is endlessly recyclable.

For the glass container industry, our products are designed to help extend the service life of neck rings, guide plates, plugs, plungers and moulds – all important parts in the manufacture of glass container. We have been serving the glass container industry for over 65 years.

Read about how we serve the glass container industry here

Franklin Bronze Precision Components, LLC., a subsidiary of the Wall Colmonoy Group, is a world leader in the supply of investment castings for the glass mould industry. Read more here

Increase Life Cycle and Minimize Replacement Downtime

Steel Mills

For Rollers, Guides, Straighteners, Bushings and Sleeves found in Steel Mills, we increase life cycle, enhance wear properties, increase corrosion resistance and minimize replacement downtime through our specialized surfacing products – Colmonoy® and Wallex®, and Precision Components, engineered cast or fully machined components.

Read more on Colmonoy® and Wallex® Surfacing Alloys for Steel Industry here

Read more on Precisely Engineered Components for the Steel Industry here

Oil & Gas

Colmonoy® was originally developed to extend the life of downhole drill bits for the oil industry.

Over the years, Wall Colmonoy has developed a line of Colmonoy® products focused specially for Oil & Gas Industry to maximize performance and extend useful life of equipment and machinery from corrosion and wear. Applications include stabilizers, steering pads, sleeves and reamers, drill bits and guides.

Wall Colmonoy also manufactures as cast or fully machined precision components. Applications include ball valves, rotors and stators, valve seats and stem guides, plugs and flow control cages, clamp plates and pads.

Both Colmonoy coatings and Precision Components protect and prolong the useful life of parts in this extremely severe environment – minimizing operational expenditure.

Read more on how we extend the useful life of downhole drilling tools in Colmonoy® News Technical Bulletin here

Product Areas

Read more about the industries we cover on our product area industry pages:

Surfacing Alloys: Maximizing performance & extending the useful life across such industries

Brazing Alloys: Joining Parts for High-Temperature & Corrosion Applications

Our Approach to Sustainability

Read about our approach to Sustainability here