“We Machine the Hard Stuff”

Fast, Flexible Turnaround to Meet Customer’s Exact Specifications

Our technical team has amassed a wealth of skill, knowledge and know-how turning designers’ and engineers’ rigorous requirements into economically viable solutions. Our expert engineers select the optimum process to suit specific needs.

Program-manage fully machined / engine ready components from barstock / castings / forgings to finished components for aerospace, automotive, power generation, oil & gas, food, and steel.

Wall Colmonoy has an ongoing commitment to high quality manufacture and with its on-site laboratory and test facilities offers certification to national and internationally recognised standards. Each machined component goes through a reassuringly stringent inspection process before final delivery. We maintain the quality assurance of ISO 9001.

Our new state of the art machining 23,500ft2 facility was officially opened in May 2012 by Wales’ First Minister, Rt. Hon Carwyn Jones A.M. Read the announcement here.

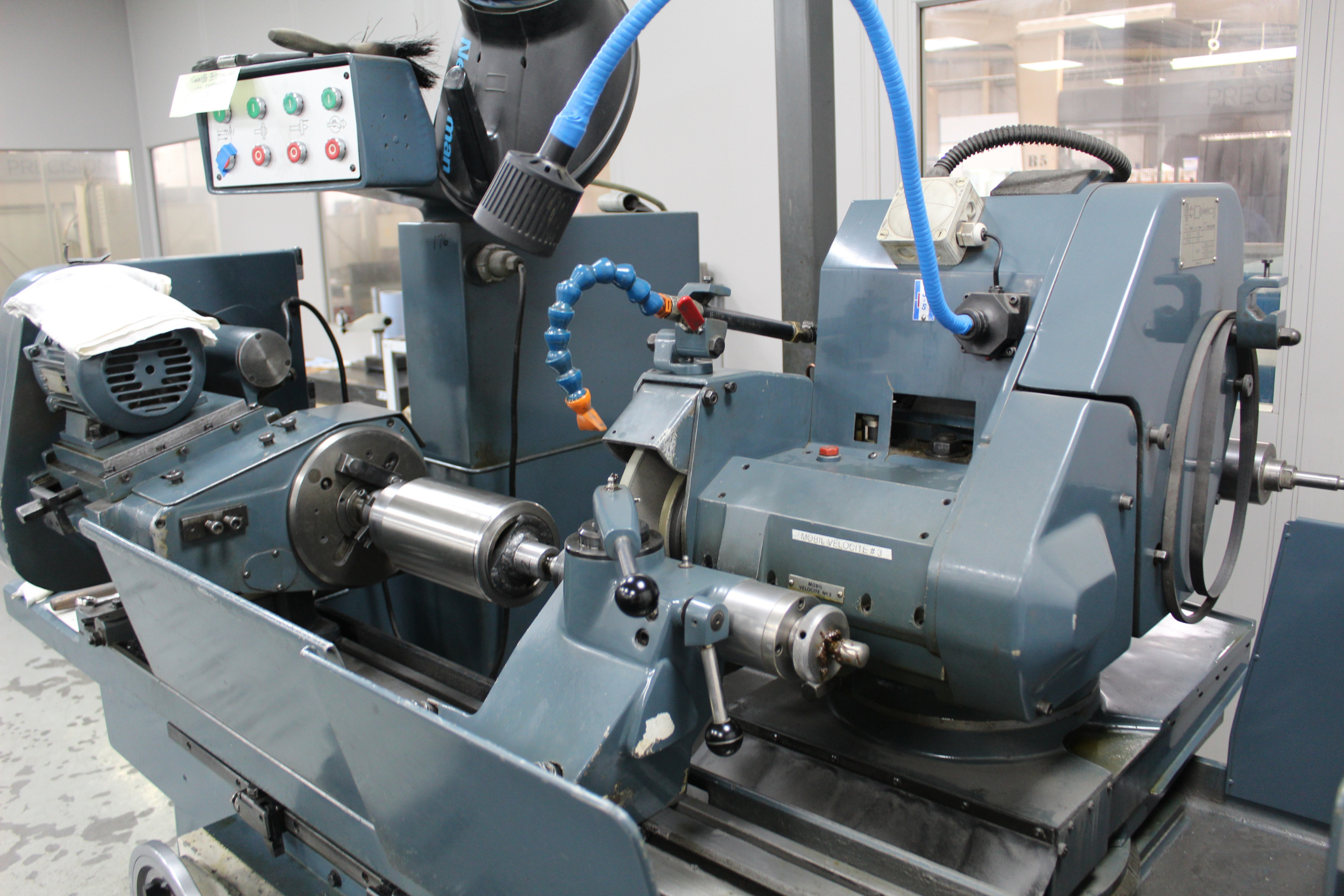

Components manufactured from centrifugal and sand castings are proof machined prior to precision finishing to drawing. Bushes and sleeves for power generation valves, galvanising steel sheet equipment and piston rings for marine engines are produced on these machines.

Precisely machined components are finished to extremely exacting dimensions on the most modern machining centres which are fully equipped with in-line measuring probes. This equipment permits finishing of components consistently and repeatedly to the most exacting tolerances. Can hold tolerances of 0.010mm.

CNC Turning Cell

CNC Large Turning Cell

The Hurco 5-Axis CNC Milling Machine benefits from an adjustable, movable Trunnion bed, allowing for flexible cutting position and versatility with machining full 5 radii to a high level of repeatability and reproducibility. This is achieved using WinMax® Software for fast effective programming of complex radii and compound angels, UltiMotion® software to reduce overall cycle time, whilst enhancing surface finish. Combined with a 40-piece tooling station this investment reduces overall cost and lead-time for our customers.

The VMX60Ui boasts maximum working area of Ø500mm and a maximum table load of 400kg.

Components requiring grinding are finished on our CNC Grinders, achieving extremely fine tolerances to better than 0.02mm (down to 0.005 microns) and high surface finish (surface finishes of 0.1 Ra). Components include parts for pumps with high processing pressures and which demand accurate metering of chemical products.

Conventional Cylindrical Grinding

CNC Cylindrical Grinding

Many components are specified to extremely low micron surface finishes for customers requiring extremely smooth, flat component surfaces. These are achieved using our state-of-the-art honing and lapping equipment.

Honing

Lapping

Machining permits complex profiles in wear-resistant materials to be produced cost-effectively and to high precision.

Wall Colmonoy’s wire cutting machines enable components from a few grams to 3 tons to be produced to finished drawing. Cast components cut on our wire machines include bushes, gears, pumps, plates, screws and more from industries such as food, pump & valves, steel, oil & gas, rubber and automotive.

Electro-Discharge Machining (EDM) Sinking

Electro-Discharge Machining (EDM) Wire-Cutting

For measurements outside of the typical ranges above, please enquire.

CONTACT

Wall Colmonoy Limited

Darren House

Alloy Industrial Estate

Pontardawe, Swansea,

Wales (U.K.) SA8 4HL

E: componentsales@wallcolmonoy.co.uk

T: +44 (0) 1792 860647