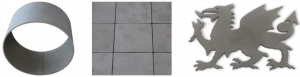

ColWear Plates can be rolled, formed and precision cut to complex geometries.

Rolled Diameter – rolled down to a 150mm radius

Formed Angles – formed using a press break down to the following critical angles:

Precision cutting – Ideal cutting methods (avoid use of temperature):

ColWear rolled into tube, with the high-performance coating on the internal diameter (left), precision cut into tiles (centre) and high complexity geometries to customer drawings (right)

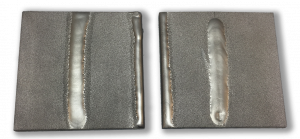

ColWear Plates can be repairable in service with the use of Wall Colmonoy Fusewelder™ Torch & equivalent Colmonoy® or Wallex® matrix powder. Fusewelder™ Torch generates consistent and coherent coating, offering further high performance in service.

ColWear 62 coating gouged to produce significant defects and then repaired using Fusewelder™ Torch & Colmonoy® powder