Vacuum powder fused and coated with Colmonoy® NiCrBSi or Wallex® CoCrNiW powder matrix, with or without Tungsten Carbide (WC), ColWear lasts significantly longer than unprotected parts in aggressive Cement & other material processing plant service environments – reducing costs, maintenance, and downtime. As a world leading manufacturer of hard-surfacing alloys, Wall Colmonoy coatings have been extending the service life of industrial parts for over 80 years.

Vacuum powder fused and coated with Colmonoy® NiCrBSi or Wallex® CoCrNiW powder matrix, with or without Tungsten Carbide (WC), ColWear lasts significantly longer than unprotected parts in aggressive Cement & other material processing plant service environments – reducing costs, maintenance, and downtime. As a world leading manufacturer of hard-surfacing alloys, Wall Colmonoy coatings have been extending the service life of industrial parts for over 80 years.

Wall Colmonoy’s range of ColWear vacuum fused wear plates offer a unique solution to the most aggressive wear problems within high-temperature corrosive, abrasive, erosive environments. ColWear plates offer superior wear resistance and lifetime well beyond the industry standard. ColWear is a great choice for products with difficult maintenance cycles because it eliminates so much waste and failure. Customers experience less downtime and far lower maintenance costs. In tough environments, ColWear offers long-term resource and cost savings. ColWear Plates outlast conventional wear plates to provide:

Range of ColWear Plates for Cement Industry:

Colmonoy® & Wallex® superalloys are not limited to the applications shown below and will improve applications subject to:

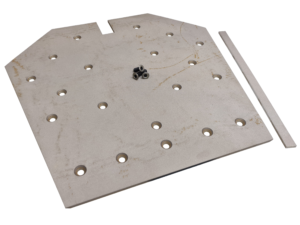

ColWear 62-1 chute wear tile

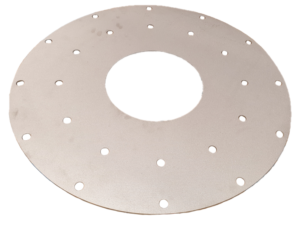

ColWear Fe air classifier blade for material processing

ColWear 69-1 industrial fan impeller liners and full wear package (including Colmonoy® coated bolts)

ColWear 62-1 mill liner for material sizing